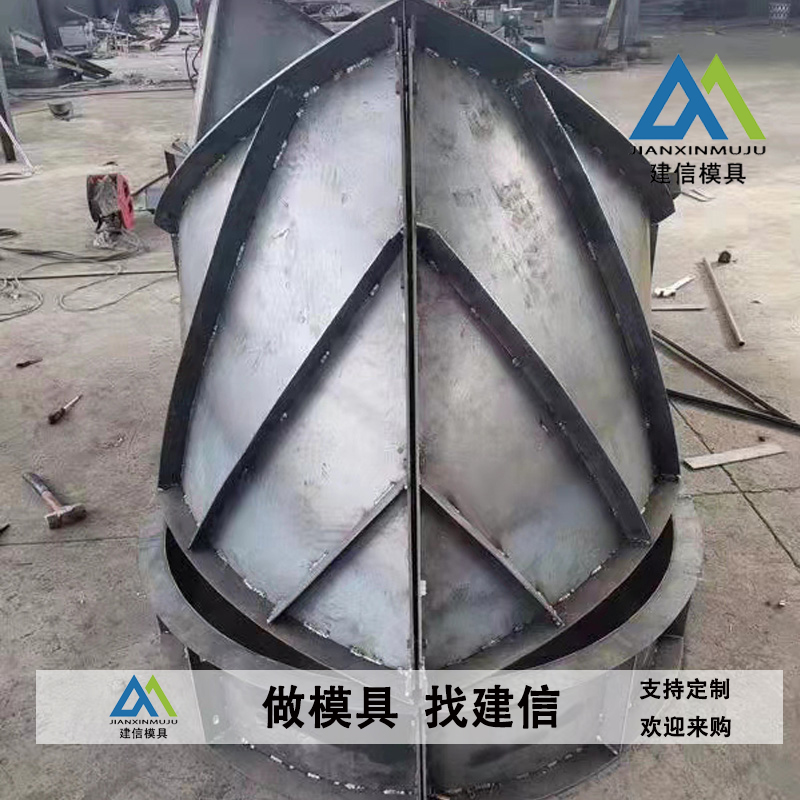

產品介紹

收費島模具現場拼裝固定完成后��,由工人在模具上涂抹機油進行保護����,然后鋪設混凝土注射管�。多工序操作后,混凝土將緩慢凝固成型��,收費島已完成澆筑����,可見各種模具的作用只是完成混凝土、水泥等砂漿的澆筑工作����。凝固砂漿具有很高的流動性是一項艱巨的任務,利用鋼模輔助凝固�,大多數模具都是用鋼板制作的,不存在變形問題�,安全運行。

收費島模具容易被周邊的環境以及天氣情況所影響���,想要完成更加順利的應用�,需要注意以下幾點:1��、高速路面施工位置是否平整,如果模具固定后出現明顯的高度不一致或者是憑借有著失誤的話�����,這會影響接下來的使用效果���,甚至造成收費島無法澆注成型,模具也會有著損壞情況的出現��。

After the mold of toll island is assembled and fixed on site, the workers shall apply engine oil on the mold for protection, and then lay concrete injection pipe. After multi process operation, the concrete will be slowly solidified and formed, and the pouring of toll island has been completed. It can be seen that the function of various molds is only to complete the pouring of concrete, cement and other mortar. The high fluidity of solidified mortar is an arduous task. Steel mold is used to assist solidification. Most molds are made of steel plate, which has no deformation problem and runs safely.